Kraftig TG | Trowel Grade Urethane Concrete Flooring

Kraftig TG Floor System

Get A Quote

Features

- Excellent adhesion to various substrates – concrete, quarry tiles, and brick pavers

- Formulated for installation ease and quick turnaround

- Very low odor – can be used in occupied areas

- Breathable flooring system – withstands high levels of moisture vapor transmission

- Does not support fungus or bacteria

- Excellent chemical and thermal shock resistance

TG (Trowel-grade)

This trowel-grade version of our urethane concrete floor coating is excellent for use in areas where the floor must be trowelled to a slope. Examples include any area with a drain or water runoff.

Versatility

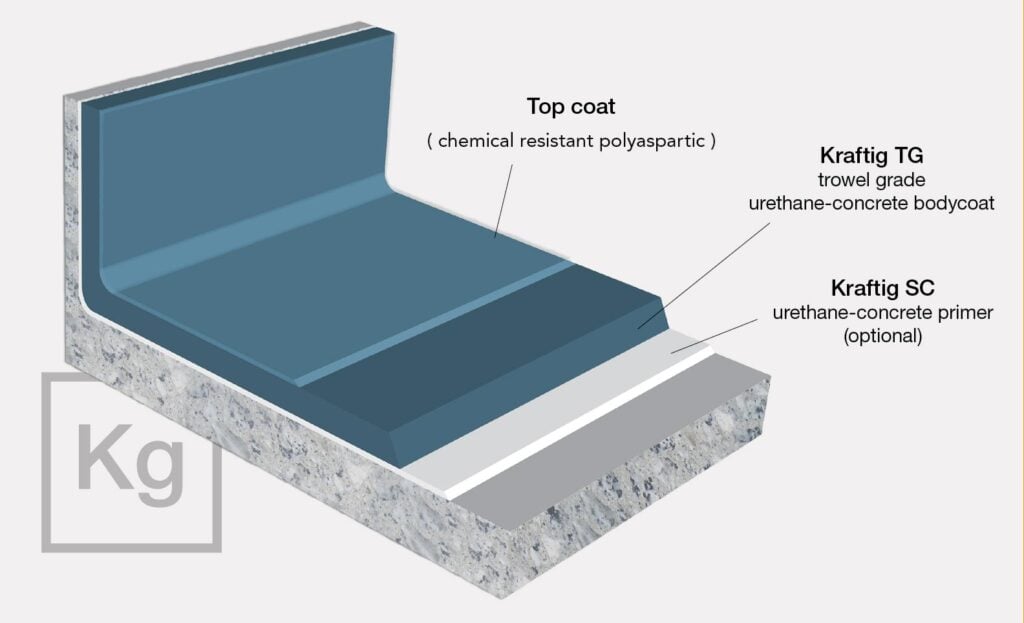

Kraftig absorbs and dissipates heat, making it usable in freezers and near industrial ovens. Installation with an optional integral cove base makes for seamless floor-to-wall installations.

Superior Performance for Demanding Jobs

- Food processing areas

- Production areas

- Bottling areas

- Cook/Chill areas

- Commercial kitchens

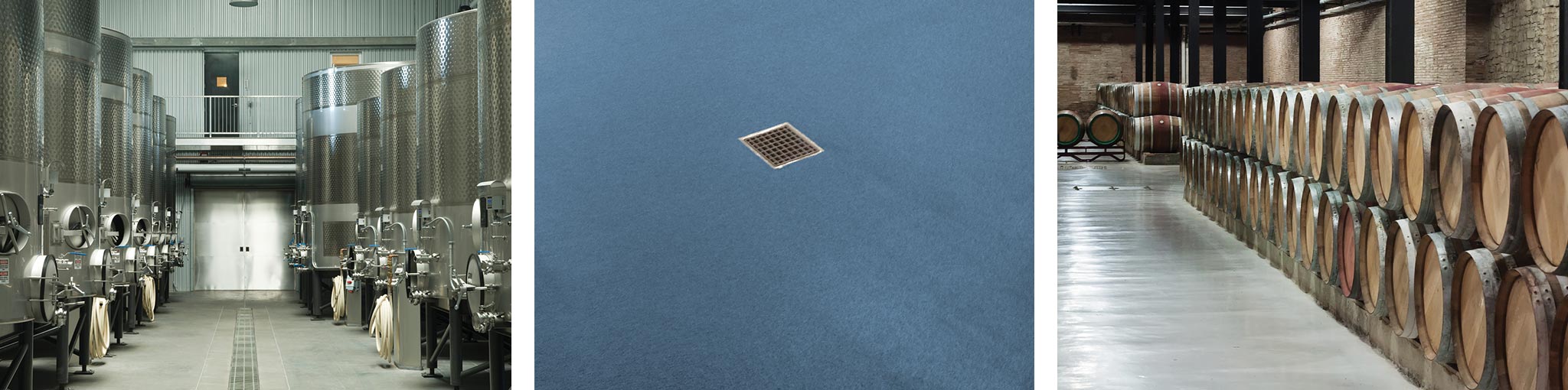

- Breweries, Wineries, Bakeries

- Pharmaceutical plants

- Sanitization and Wash areas

- Chemical processing areas

- Loading and Unloading docks

The Superhero of Floors.

Impervious. Hygienic. Extraordinary.

Kraftig TG is a heavy-duty, trowel-grade urethane concrete floor system engineered for demanding environments where floors must be sloped toward drains and withstand constant moisture, impact, and aggressive cleaning. This seamless urethane concrete topping is ideal for wet processing areas such as food and beverage plants, commercial kitchens, breweries, distilleries, cold storage, and wash-down zones that require reliable drainage and long-term performance.

As a cementitious urethane (urethane cement) system, Kraftig TG delivers outstanding resistance to thermal shock, hot water, steam cleaning, and a wide range of chemicals commonly found in food processing and industrial facilities. The dense, non-porous surface will not support the growth of fungus or bacteria, helping facilities maintain strict sanitation, while reducing long-term maintenance costs.

Kraftig TG bonds tenaciously to properly prepared concrete, quarry tile, and brick, and tolerates high moisture vapor emission, making it suitable for both new construction and renovation projects where existing substrates may be challenging. Its built-in textured surface can be adjusted to provide slip resistance in constantly wet or greasy areas, improving worker safety around drains, cook lines, bottling lines, and loading docks.

Installed at thicknesses typically between 1/4 inch and 3/8 inch, Kraftig TG creates a robust urethane concrete surface that resists cracking, chipping, and delamination under heavy traffic and thermal cycling. When combined with an integral cove base, the system forms a seamless floor-to-wall transition that eliminates dirt-catching joints and simplifies wash-down and sanitation procedures.

Typical applications for Kraftig TG urethane concrete include food processing and packaging areas, commercial kitchens, dairies, breweries and distilleries, meat and poultry plants, bakeries, pharmaceutical production, laboratories, cold storage and freezers, and chemical processing zones. In all these environments, Kraftig TG provides a long-lasting, low-maintenance flooring solution that outperforms conventional epoxy systems where thermal shock, moisture, and heavy abuse are daily realities.